Our Production Monitoring and Management System (20/20) is a real-time shop floor data collection and management system designed to enhance the production management to a higher level using innovative tools.

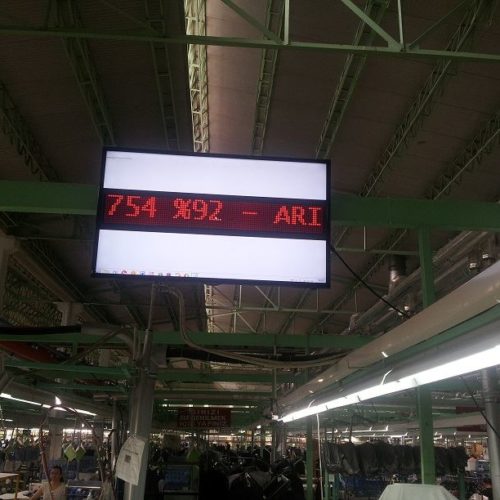

• Improves productivity by leveraging production monitoring and motivating the workers to meet the standards.

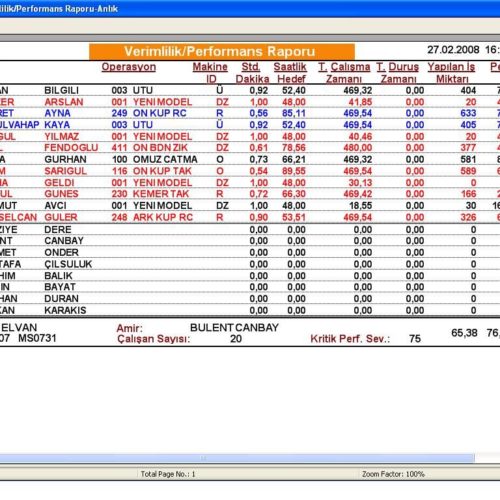

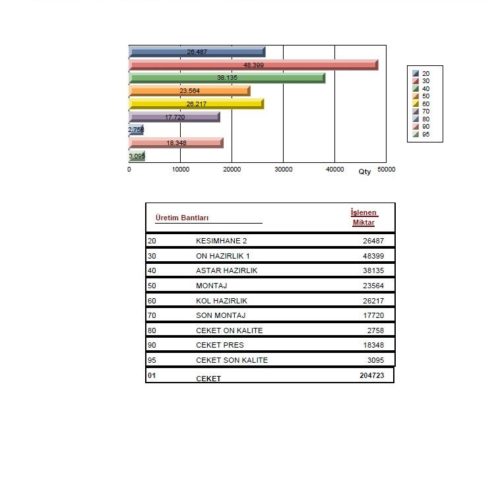

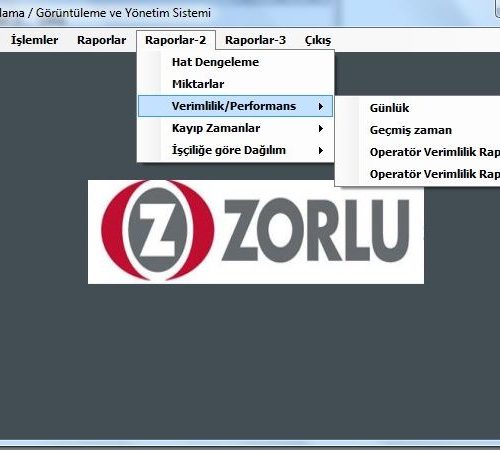

• Provides detailed analysis allowing users to monitor performance and labor costs in terms of employee, operation, part/model number, order, department or subdepartment.

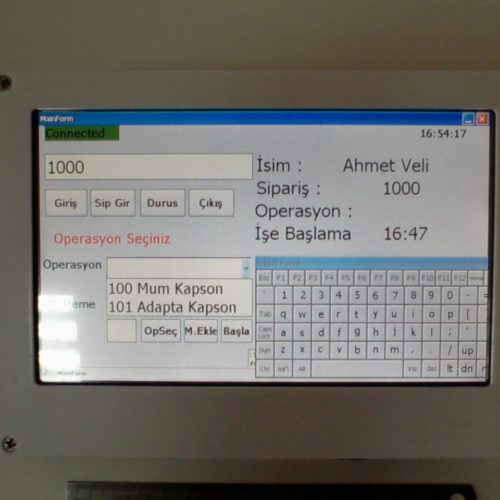

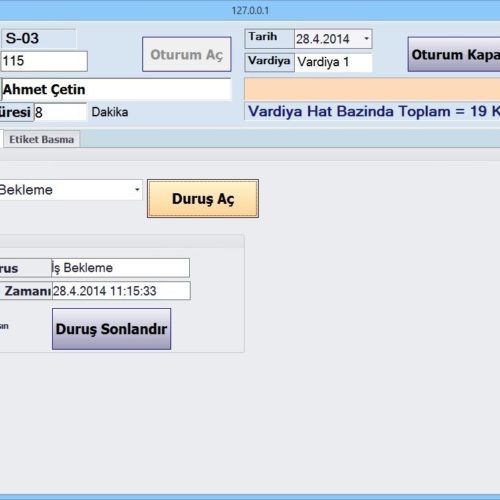

• Lowers overhead costs by eliminating manual data entry, eliminating data redundancy and therefore by eliminating/reducing errors.

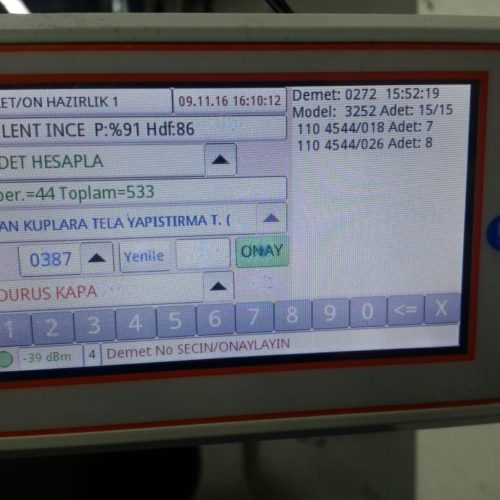

• Allows full product traceability by customer order, lot/bundle number and/or work order number.

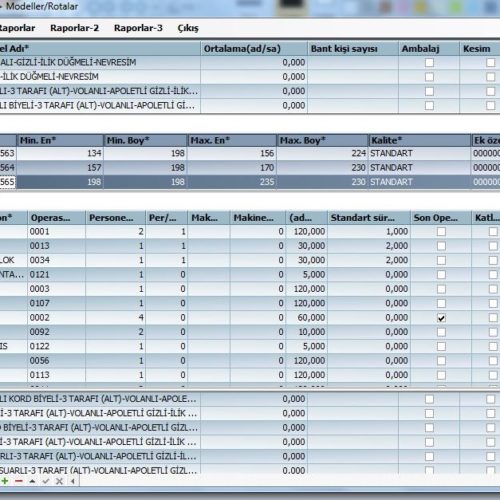

• Enables engineers to use the reported information to determine the precise cause of any production-related problem and helps them to take the necessary actions to resolve it.

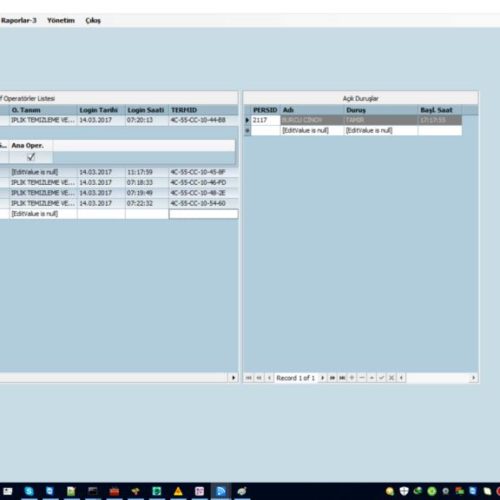

• Provides proactive shop floor management.

• Reports data on time.

• Constitutes a continuous improvement tool for the managers to better lead production operations as well as continuous total quality improvement programs.

• Helps optimize line balancing and flow efficiency.

• Helps optimize engineering and human resources.

• Identifies poor operator performance before it causes a problem.

• Helps managers see job training results faster.

• Helps identify problems with standard allowed times.

• Helps troubleshoot line issues by allowing access to detailed historical information.